Te parani o te kowiri tira

1. Maamaa

Ko te raruraru tuatahi i roto i te parai kowiri tira ko te kiriata waikura i runga i te mata ka tino pa ki te makuku me te horapa o te konuhono.He nui te Cr o nga tira kowiri rereke, kei roto ano etahi Ni, Ti, Mn, Mo, Nb me etahi atu huānga, ka taea te hanga i etahi momo waikura, waikura hiato ranei i runga i te mata.I roto ia ratou, ko nga waikura Cr2O3 me TiO2 o Cr me Ti he tino pumau, he uaua ki te tango.I te wa e pupuhi ana i te hau, me whakamahi te rere kaha hei tango;I te wa e pupuhi ana i roto i te hau whakamarumaru, ka taea te whakaheke i te kiriata waikura anake i roto i te hau tino ma me te iti o te tomairangi me te nui o te pāmahana;I roto i te korehau brazing, he mea tika ki te whai nui korehau me te nui pāmahana ki te whakatutuki i te pānga brazing pai.

Ko tetahi atu raruraru o te pupuhi kowiri tira ko te paanga whakawera he tino paanga ki te hanganga o te whakarewa turanga.Ko te wera whakawera whakawera o austenitic kowiri tira kaua e teitei ake i te 1150 ℃, ki te kore ka tino tupu te witi;Mena karekau he kowiri tira austenitic he huānga pumau Ti, Nb ranei he nui te waro, ka karohia te whakamahana i roto i te pāmahana tairongo (500 ~ 850 ℃).Kia kore ai e heke te parenga waikura na te rerenga o te chromium carbide.Ko te kowhiringa o te wera wera mo te martensitic kowiri tira he kaha ake.Ko tetahi ko te ki te ōrite te pāmahana brazing ki te pāmahana tinei, kia rite ki te whakakotahi i te tukanga brazing ki te tukanga maimoatanga wera;Ko tetahi atu, me iti ake te wera o te whakamahana i te wera whakamahana kia kore ai e ngohe te whakarewa o te turanga i te wa o te whakamahana.Ko te maataapono kowhiringa o te whakamaarama whakamaarama o te kowiri tira he rite ki tera o te kowiri tira martensitic, ara, me taurite te pāmahana whakawera ki te punaha maimoatanga wera kia whiwhi ai i nga taonga miihini pai rawa atu.

I tua atu i nga raru nui e rua i runga ake nei, he ahua ka pakaru te ahotea i te wa e whakapaoho ana i te kowiri tira austenitic, ina koa i te wa e whakapaoho ana ki te konupora konutea whakakī whakarewa.Hei karo i te pakaru o te ahotea, me whakamau te ahotea i mua i te whakamahana, ka whakamahana te mea mahi i te wa o te parai.

2. Rauemi brazing

(1) E ai ki nga whakaritenga whakamahi o te kowiri tira kowiri, ko nga konganuku whakakikorua e whakamahia nuitia ana mo nga raima kowiri tira ko te Tiini Lead te whakakikorua i te whakarewa, te hiriwa, te hiriwa, te parahi, te konupora, te konupora, te nickel. whakarewa whakakī whakakī me te whakarewa utu nui.

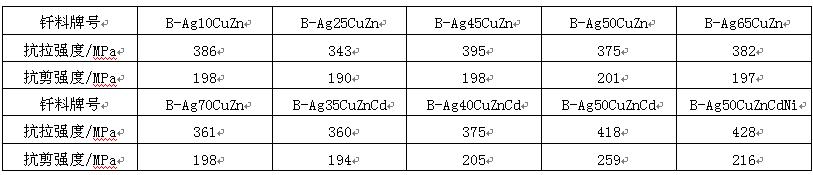

Kei te whakamahia te nuinga o te konupuku mata tine mo te whakakoi kowiri tira, a he pai ki te whai kiko tine teitei.Ko te teitei ake o te ihirangi tine o te konuhini, te pai ake o tona makuku ki runga kowiri tira.Ko te kaha kutikuti o te 1Cr18Ni9Ti kowiri tira kowiri tira kua whakararangihia me te maha o nga kaitarai tiini noa kua whakarārangihia ki te Ripanga 3. Na te iti o te kaha o nga hononga, ka whakamahia noa mo nga waahanga parani me te iti o te kaha o te kawe.

Ripanga 3 te kaha kutikuti o te 1Cr18Ni9Ti he kowiri tira i whakakikoruatia ki te whakarewa tine

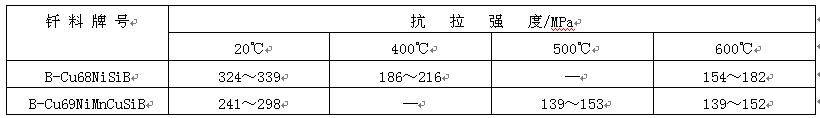

Ko nga konganuku whakakii i runga i te hiriwa ko nga konganuku whakakii nui e whakamahia ana mo te parai kowiri tira.I roto i a raatau, ko te konutea konupora hiriwa me nga konganuku konupora konupora kadmium whakakī i te nuinga o te whakamahi na te mea he iti te paanga o te pāmahana parai ki nga ahuatanga o te whakarewa turanga.Ko te kaha o nga hononga kowiri tira ICr18Ni9Ti kua whakarārangihia ki te Ripanga 4. Ko nga hononga kowiri tira i whakakikoruatia me nga raima hiriwa he iti rawa te whakamahi i roto i nga panui tino kino, a ko te pāmahana mahi o nga hononga kaore e neke atu i te 300 ℃. .A, no te brazing kowiri tira kahore nickel, i roto i te tikanga ki te karo i te waikura o brazed hononga i roto i te taiao takawai, brazing whakakī konganuku ki atu nickel ka whakamahia, pērā i b-ag50cuzncdni.I te wa e whakakorikori ana i te martensitic kowiri tira, kia kore ai e ngohe te whakarewa o te turanga, me whakamahi te whakarewa whakakikorua me te wera wera kia kaua e neke ake i te 650 ℃, penei i te b-ag40cuzncd.I te wa e whakakorikori ana i te kowiri tira i roto i te hau whakamarumaru, hei tango i te kiriata waikura i runga i te mata, ka taea te whakamahi i te lithium kei roto ko te rewharewha whakamarumaru whaiaro, penei i te b-ag92culi me te b-ag72culi.I te wa e whakakorikori ana i te kowiri tira i roto i te korehau, kia pai tonu te makuku o te whakarewa whakakī i te mea karekau he huānga penei i te Zn me te CD he ngawari ki te whakaeto, ka taea e te whakarewa whakakī hiriwa kei roto nga huānga penei Mn, Ni me RD. kua tohua.

Ripanga 4 te kaha o te hononga kowiri tira ICr18Ni9Ti i whakakikoruatia ki te whakarewa whakakī i runga i te hiriwa

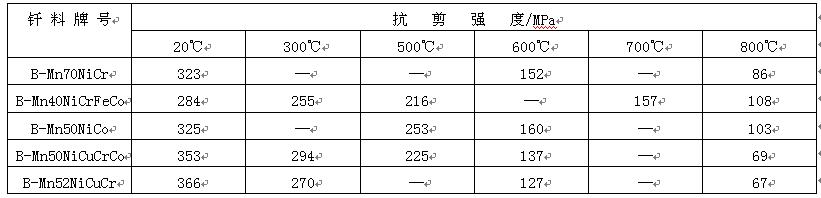

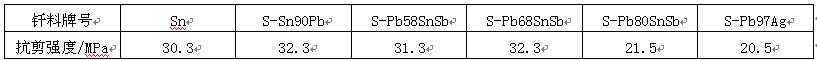

Ko nga konganuku whakakii parai te parahi e whakamahia ana mo te tarai i nga tira rereke ko te nuinga o te parahi parakore, te nickel parahi me te konupora konupora konupora whakakii whakarewa.Ka whakamahia te nuinga o te whakarewa parahi parakore mo te whakamarumaru i raro i te whakamarumaru hau me te korehau.Ko te pāmahana mahi o te hononga kowiri tira e kore e neke ake i te 400 ℃, engari he ngoikore te aukati o te waikura o te hononga.Ko te konukura nickel brazing whakakī whakarewa te nuinga o te whakamahia mo te mura mura me te parai whakauru.Ko te kaha o te huinga parani 1Cr18Ni9Ti kowiri tira e whakaatuhia ana i te Ripanga 5. Ka kitea he rite te kaha o te hononga ki te whakarewa turanga, a, he tiketike te wera o te mahi.Cu Mn co brazing whakakī whakarewa te nuinga whakamahia mō te brazing martensitic kowiri tira i roto i te huru tiaki.Ko te kaha o te hono me te pāmahana mahi he rite ki te hunga kua whakakikoruatia ki te whakarewa koura.Hei tauira, ko te 1Cr13 he kowiri tira i whakakikoruatia ki te b-cu58mnco solder he rite tonu te mahi ki te kowiri tira o te kowiri tira i whakakikoruatia ki te b-au82ni solder (tirohia te Ripanga 6), engari ka tino heke te utu whakaputa.

Ripanga 5 te kaha kutikuti o te 1Cr18Ni9Ti he kowiri tira i whakakikoruatia ki te wera teitei o te turanga parahi whakarewa whakarewa.

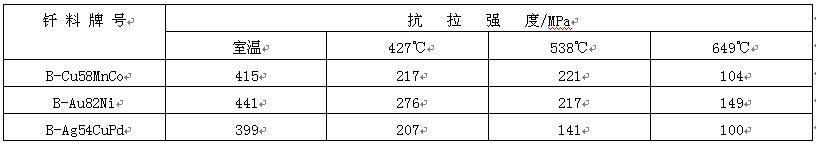

Ripanga 6 te kaha kutikuti o te 1Cr13 he kowiri tira hono

Ko te nuinga o nga konganuku whakakikorua o te konupora e whakamahia ana mo te whakamarumaru o te hau, a ko te ma o te hau e hiahiatia kia teitei.Hei karo i te tipu o te witi o te konganuku turanga, me kowhiria te whakarewa whakakī whakakī me te wera o te wera i raro iho i te 1150 ℃.Ka taea te whiwhi i te painga pai mo nga hononga kowiri tira i whakakikoruatia ki te konupora i runga i te konupora, e whakaatuhia ana i te Ripanga 7. Ka tae te pāmahana mahi o te hononga ki te 600 ℃.

Ripanga 7 te kaha kutikuti o te hononga kowiri tira lcr18ni9fi he mea parai ki te whakarewa whakakī i runga i te konupora

I te wa e parai ana te kowiri tira ki te whakarewa nickel base filler, he pai te mahi o te hononga ki te pāmahana teitei.Ko tenei whakarewa whakakii ka whakamahia mo te whakamarumaru whakamarumaru hau me te parai korehau.Hei karo i te raru ka nui ake te hanga o nga puhui pakaru i roto i te hononga brazed i te wa o te hanga hononga, e tino whakaiti ana i te kaha me te kirihou o te hononga, me whakaitihia te mokowhiti o te hononga ki te whakarite kia ngawari nga waahanga ki te hanga i te waahanga pakaru i roto i te waahanga. kua tino horahia te konutai ki te whakarewa turanga.Hei aukati i te tupu o te tipu o te witi whakarewa na te roa o te wa e pupuri ana i te wera wera, ka taea te tango i nga tikanga o te pupuri i te wa poto me te whakamaarama whakamaarama i te pāmahana iti (ka whakaritea ki te wera wera) i muri i te whakapiri.

Ko nga konganuku whakakikorua whakarewa maitai e whakamahia ana mo te raima kowiri tira ko te nuinga o nga konganuku whakakii koura me te palladium kei roto nga konganuku whakakii, ko te mea tino angamaheni ko te b-au82ni, te b-ag54cupd me te b-au82ni, he pai te makuku.Ko te hononga kowiri tira he nui te kaha o te pāmahana teitei me te aukati o te waikura, a ko te teitei o te pāmahana mahi ka eke ki te 800 ℃.He rite nga ahuatanga o te B-ag54cupd ki te b-au82ni me te iti o te utu, na reira ka huri te b-au82ni.

(2) Ko te mata o te kowiri tira i roto i te rere me te hau oumu kei roto i nga waikura penei i te Cr2O3 me te TiO2, ka taea anake te tango ma te whakamahi i te rere me te mahi kaha.I te wa e whakapuruhia ana te kowiri tira ki te konupuku mata tine, ko te rerenga pai ko te wairewa wai waikawa phosphoric, wairewa waikawa konutai waikura ranei.He poto te wa mahi o te wairewa wai waikawa phosphoric, no reira me whakamahi te tikanga whakamahana tere.Fb102, fb103, fb104 fluxes ranei ka taea te whakamahi mo te raima kowiri tira me nga konganuku whakakii i runga i te hiriwa.I te wa e whakapaoho ana i te kowiri tira me te whakarewa whakakii i runga i te parahi, ka whakamahia te rere o te fb105 na te nui o te werawera.

I te wa e whakawerahia ana te kowiri tira i roto i te oumu, ka whakamahia te hau korehau me te hau whakamarumaru penei i te hauwai, te argon me te haukini pirau.I roto i te korehau brazing, me iti iho te pehanga korehau i te 10-2Pa.I te wa e pupuhi ana i roto i te hau whakamarumaru, kaua te toma o te hau e teitei ake i te -40 ℃ Mena kaore i te nui te maa o te hau, kaore ranei i te teitei te wera o te wera, ka taea e te iti o te rere o te hau, penei i te boron trifluoride. ka taapiri atu ki te hau.

2. Hangarau parani

Ko te kowiri tira me tino horoi ake i mua i te parai hei tango i te hinu me te kiriata hinu.He pai ake te parai i muri tonu i te horoi.

Ka taea e te kowiri tira te tango i te mura, te whakaurunga me nga tikanga whakamahana reo.Ko te oumu mo te wera i roto i te oumu me pai te punaha whakahaere i te pāmahana (ko te rereke o te wera wera me ± 6 ℃) ka taea te whakamatao tere.I te wa e whakamahia ana te hauwai hei hau whakamarumaru mo te whakamarumaru, ko nga whakaritenga mo te hauwai e whakawhirinaki ana ki te wera wera me te hanganga o te whakarewa turanga, ara, ko te iti iho o te wera o te wera, ko te nui ake o te whakarewatanga o te whakarewatanga o te whakarewa, me te heke iho o te tomairangi. ka hiahiatia te tohu hauwai.Hei tauira, mo nga tira kowiri tira martensitic penei i te 1Cr13 me te cr17ni2t, i te wa e whakamahana ana i te 1000 ℃, me iti ake te hauwai o te hauwai i te -40 ℃;Mo te 18-8 chromium nickel he kowiri tira kaore he whakapumau, me iti ake te hauwai o te hauwai i te 25 ℃ i te wa e whakamahana ana i te 1150 ℃;Heoi, mo te 1Cr18Ni9Ti he kowiri tira kei roto ko te titanium stabilizer, me iti iho te hauwai hauwai i te -40 ℃ i te wa e wera ana i te 1150 ℃.A, no te brazing ki te tiaki argon, me te ma o argon te ki kia teitei.Mena ka whakakikoruatia te parahi, te nickel ranei i runga i te mata o te kowiri tira, ka taea te whakaiti i te whakaritenga mo te ma o te hau whakamarumaru.Hei whakarite i te tangohanga o te kiriata waikura i runga i te mata o te kowiri tira, ka taea hoki te taapiri i te rerenga hau BF3, ka taea hoki te whakamahi i te lithium, te boron ranei kei roto i te konupuku whaiaro.A, no te korehau brazing kowiri tira, nga whakaritenga mo te korehau tohu whakawhirinaki i runga i te pāmahana brazing.Na te pikinga o te wera wera, ka taea te whakaheke i te korehau e hiahiatia ana.

Ko te tukanga matua o te kowiri tira i muri i te paraihe ko te horoi i te rerenga toenga me te aukati rerenga toenga, me te kawe i te maimoatanga wera wera i muri i te wa e tika ana.I runga i te rere o te rere me te tikanga parai i whakamahia, ka taea te horoi i te toenga rere ki te wai, te horoi miihini, te horoi matū ranei.Mena ka whakamahia te abrasive ki te horoi i te toenga rerenga, kiriata waikura ranei i roto i te waahi wera e tata ana ki te hononga, me whakamahi te onepu me etahi atu matūriki pai kore-whakarewa.Ko nga waahanga i hangaia mai i te martensitic kowiri tira me te ua e whakapakeke ana i te kowiri tira e hiahia ana ki te maimoatanga wera kia rite ki nga whakaritenga motuhake o te rauemi i muri i te parai.Ko nga hononga kowiri tira i whakakikoruatia ki te Ni Cr B me te Ni Cr Si nga konganuku whakakii i te nuinga o te wa ka tukuna ki te maimoatanga wera whakamaarama i muri i te pupuhi ki te whakaiti i nga whakaritenga mo te waahi pupuhi me te whakapai ake i te hanganga moroiti me nga taonga o nga hononga.

Wā tuku: Hune-13-2022